Table of Contents

Importance of Roof Support in Underground Mines

Roof support in underground mines is essential for:

- Preventing major collapses of the mine roof.

- Protecting miners from small rock falls from the immediate roof skin.

- Controlling deformations to ensure mine openings remain accessible for entry, escape, and ventilation.

- Ensuring continuity of ore production to maintain profitability.

- Protecting expensive underground machinery, such as those used in longwall mining.

When is Roof Support Necessary?

Roof support is required in the following conditions:

- Presence of weak or unconsolidated rock in the roof and walls of the mine.

- Geological structures like shear zones that weaken rocks.

- Existence of voids and spaces in the rock structure.

- Presence of clay beds prone to shrinking and expanding, which can cause rock sliding, especially in wet conditions.

- Underground water that accelerates chemical weathering, leading to loose rocks and corrosion of mining equipment.

Materials Used for Roof Support in Underground Mines

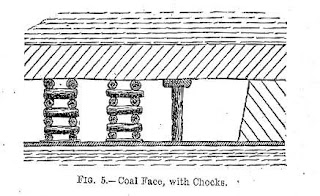

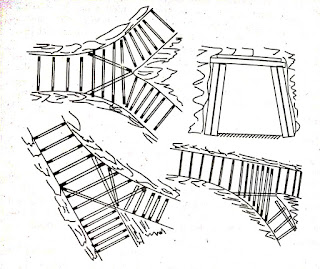

- Timber – Commonly used for props, bars, chocks, and laggings, often made from sal or teak.

- Iron and Steel – Used in the form of bars, props, arches, corrugated sheets, and roof bolts.

- Brick or Masonry Walls – Constructed using bricks or stone for added support.

- Reinforced or Precast Concrete – Used as roadway lining.

- Pack Walls – Made from dirt bands, shales, and road-ripping materials.

- Filling Materials – Includes sand, earth, boiler ash, washery rejects, slag from iron smelting, and crushed stone for void filling.

Timber as a Support Material

Timber is widely used in underground mining due to its availability and affordability. Its advantages include:

- Easy to cut to the desired length.

- Provides early warning signs of failure by swelling before breaking.

However, timber has some disadvantages:

- Cannot be reused after deterioration.

- Prone to swelling due to moisture and decay from bacteria and fungi.

- Short lifespan unless treated to resist corrosion, insects, and bacteria.

Timber Diseases in Mines

- Dry Rot – Causes timber to become soft, weak, and prone to warping.

- Wet Rot – Leads to decay and fungal infestation in damp conditions.

Wood Drying (Seasoning Lumber)

Wood drying reduces the moisture content before use. The process starts from the exterior and moves towards the center. Once dried, wood attains equilibrium with the surrounding air.

Methods of Wood Drying

- Air Drying

- Timber is stacked on raised foundations in a well-ventilated, cool, and dry place.

- Drying time depends on climatic conditions and air movement.

- This method is cost-effective but time-consuming, taking months to years.

- Improper air drying can cause cracking or splitting in extreme weather.

- Kiln Drying

- Involves controlled heating using gas, electricity, or steam.

- Ensures faster and uniform drying, overcoming weather-related limitations.

- Kills fungi and insects when temperatures exceed 60°C.

- More efficient for large-scale drying but requires high capital investment.

Comparison of Air Drying and Kiln Drying

- Air Drying:

- Difficult to achieve moisture content below 18%.

- Dependent on climatic conditions, making drying times unpredictable.

- Cost-effective but requires large storage space.

- Kiln Drying:

- Faster drying with precise moisture control.

- Higher initial investment but better long-term efficiency.

- Protects against fungal and insect infestations.

Elements of Kiln Drying

- Construction Materials – Kilns are made of brick, cement slabs, or prefabricated aluminum with thermal insulation.

- Heating – Uses steam heat exchangers or hot gas pipes; electricity is rarely used.

- Humidification – Controlled by introducing live steam and ensuring proper ventilation.

- Air Circulation – Essential for even heat distribution and moisture removal.

Timber Storage in Mines

Timber is generally air-dried for long periods before use. In colliery yards, timber is stacked above ground to ensure:

- Air circulation for drying.

- Prevention of dampness.

- Regular turnover to avoid rot and fungal attacks.

Tags

Mining, Roof Support, Underground Mining, Timber Drying, Air Drying, Kiln Drying, Mine Safety, Mining Equipment Protection.

Leave a comment