Key Points

- The optimal block size in open-pit mining varies based on mine-specific factors like geology and equipment, but research suggests typical sizes range from 10–20 meters in height and 20–50 meters in width and length.

- It seems likely that block height equals bench height, usually 12–15 meters for large mines, while width and length depend on shovel and truck operations.

- The evidence leans toward block sizes being determined by mining equipment capabilities, with no universal standard due to diverse mine conditions.

Overview

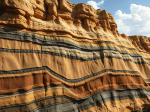

Open-pit mining involves extracting minerals by creating large, stepped excavations called benches. The block size, a critical aspect of mine planning, refers to the three-dimensional units used to model and extract ore, influencing efficiency and cost. While there’s no one-size-fits-all answer, understanding typical ranges can help grasp the concept.

Typical Dimensions

- Height (Z-axis): Typically matches the bench height, often 10–20 meters, with common values around 12–15 meters for large mines, as seen in industry practices (Open-pit mining).

- Width and Length (X and Y axes): Generally range from 20–50 meters, determined by the size of mining equipment like shovels and the efficiency of shovel-truck systems, as detailed in recent studies (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency).

Unexpected Detail: Equipment Influence

An interesting aspect is how block size isn’t just about geology but heavily influenced by equipment, such as shovel bucket widths (often 20–30 meters in large operations), which can affect the horizontal dimensions more than expected, impacting operational efficiency.

Survey Note: Detailed Analysis of Optimal Block Size in Open-Pit Mining

Open-pit mining, a surface mining method, involves extracting minerals by creating large, stepped excavations known as benches. The block size, a fundamental unit in mine planning, refers to the three-dimensional blocks used to model and extract ore, playing a crucial role in production scheduling, cost optimization, and resource estimation. This survey note provides a comprehensive analysis, drawing from recent research, industry practices, and case studies, to address the optimal block size in open-pit mining as of March 9, 2025.

Factors Influencing Block Size

The optimal block size is not a fixed value but depends on several factors, including geological characteristics, mining equipment capabilities, and economic considerations. Research highlights the importance of aligning block size with the Selective Mining Unit (SMU), the smallest volume that can be selectively mined and handled separately, to ensure accurate reserve estimation (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency).

- Geological Factors: The nature of the ore body, including grade variability and deposit geometry, influences block size. Smaller blocks improve grade estimation accuracy but are limited by the density of exploration data, such as borehole spacing.

- Technical Factors: Mining parameters like bench height, slope angle, and equipment size (e.g., shovel width, truck capacity) directly affect block dimensions. For instance, bench height determines the Z-axis size, while shovel width influences the X-axis size.

- Economic Factors: Block size impacts mining selectivity, dilution, and operational costs. Larger blocks may reduce computing power needs but can lead to grade dilution, affecting net present value and cash flow, as noted in studies (Block size selection and its impact on open-pit design and mine planning).

Determination Methods

Several methods have been proposed to determine optimal block size, reflecting the complexity of the decision:

- Ruiseco’s Guidelines: Suggest block size should be greater than 1/4 the average distance between exploration boreholes and at least 1/3 the borehole distance, with block height not exceeding bench height (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency).

- Stevanovic et al.: Recommend 1/3 to 1/2 borehole spacing for X and Y directions, with Z constrained by bench height, using the Analytic Hierarchy Process (AHP) for optimization.

- Hayati et al.: Used the VIKOR method, determining a 10 m block size for the Angouran mine, illustrating mine-specific variations.

- Leuangthong et al. and Abdollahei: Employed AHP and fuzzy decision-making methods, considering equipment, mining method, and sedimentary environment, highlighting the integration of multiple factors.

A recent study proposed a novel method integrating mining parameters and shovel-truck operation efficiency, using a closed shell three-dimensional geological model to determine block size, demonstrating superiority over traditional block models (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency).

Typical Dimensions and Case Studies

While no universal standard exists, typical block sizes can be inferred from industry practices and case studies:

- Height (Z-axis): The Z-axis size is typically equal to the bench height, which ranges from 10 to 20 meters, with common values of 12–15 meters for large mines. For example, the Baorixile Open-Pit Mine in China uses a bench height of 15 m (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency). Wikipedia notes large mine benches are generally 12 to 15 meters thick (Open-pit mining).

- Width and Length (X and Y axes): The X-axis size is often determined by shovel width, ranging from 15 to 30 meters in case studies, while Y-axis size depends on shovel-truck operation efficiency, typically 20–50 meters. In the Baorixile case, X-axis sizes were calculated as 26 m for WK-35 shovel, 25 m for WK-10B, and so on, with mining belt widths of 25 m, 20 m, etc., suggesting a range of 20–30 meters for X (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency). Industry sources indicate bench widths are generally 20–40 meters (Open-Pit Mining Definition).

A comparative analysis in the study compared block models of 3×3×3, 6×6×6, and 12×12×12, likely in meters, with the proposed method showing higher accuracy, though these sizes seem small compared to case study calculations, suggesting context-specific interpretations (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency).

Impact of Equipment

An unexpected detail is the significant influence of mining equipment on block size, beyond geological factors. Shovel bucket widths, typically 5–10 meters, and overall shovel operation widths (20–30 meters in large mines) directly affect X and Y dimensions. For instance, the Baorixile case used shovels with capacities like 35 m³, 10 m³, and 12 m³, with mining belt widths of 25 m, 20 m, etc., impacting block size calculations (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency). This equipment dependency highlights operational efficiency, with larger shovels allowing for larger block sizes to optimize production.

Challenges and Considerations

Determining optimal block size faces challenges, including:

- Accuracy vs. Practicality: Smaller blocks improve grade estimation but are constrained by computing power and exploration data density. Larger blocks reduce dilution but may miss grade variability, affecting economic outcomes (Block size selection and its impact on open-pit design and mine planning).

- Mining Dilution: Jara et al. found larger blocks improve ore body quality but decrease average grade and discounted cash flow, while smaller blocks reduce boundary grade errors, illustrating a trade-off (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency).

Case Study: Baorixile Open-Pit Mine

The Baorixile Open-Pit Mine, located in Inner Mongolia, China, provides a concrete example:

- Location and Scale: 50.72 km², operational since 1998, capacity 35 million t/a.

- Mining Parameters: Bench height 15 m, bench slope angle 65°–70°, mining belt widths 25 m (WK-35), 20 m (WK-10B, WK-12), 10 m (4 m³ hydraulic backhoe).

- Equipment: Shovels (35 m³, 10 m³, 12 m³, 4 m³), trucks (220t, 91t, 60t), with efficiencies like P_WK-35=0.96, P_MT4400AC-220T=0.93.

- Block Model: X-axis sizes calculated as 26 m (WK-35), 25 m (WK-10B), etc., Z-axis 15 m, Y-axis determined by operation efficiency, ensuring volume accuracy and alignment with practical conditions.

This case study illustrates how block sizes are tailored, with X-axis around 20–30 m, Z-axis 15 m, and Y-axis variable, aligning with the 20–50 m range for horizontal dimensions (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency).

Comparative Analysis

The study compared regular block models (3×3×3, 6×6×6, 12×12×12) with the proposed method, showing higher errors in larger regular blocks (max 7.4252% for 12×12×12), suggesting these sizes (likely in meters) are less practical for large mines compared to equipment-based calculations, reinforcing the need for mine-specific optimization (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency).

Equations and Calculations

The study provided equations for block size determination:

- Volume (V = \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\frown}$}}{X} \cdot \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\frown}$}}{Y} \cdot \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\frown}$}}{Z}).

- X-axis size (\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\frown}$}}{X} = \frac{\tilde{Q}}{A \cdot h}), where (\tilde{Q}) is daily shovel efficiency, A is mining belt width, h is bench height.

For example, for WK-35 shovel, (\tilde{Q}=9869.50) m³/d, A=25 m, h=15 m, (\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\frown}$}}{X} \approx 26.32) m, illustrating the calculation process (Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency).

Summary Table: Typical Block Size Ranges

| Dimension | Typical Range (meters) | Notes |

|---|---|---|

| Height (Z-axis) | 10–20 | Equals bench height, commonly 12–15 m for large mines |

| Width (X-axis) | 20–40 | Determined by shovel width, often 20–30 m in case studies |

| Length (Y-axis) | 20–50 | Depends on shovel-truck operation efficiency, variable by mine |

This table summarizes the ranges, reflecting industry practices and case study data, with no universal standard due to mine-specific variations.

Conclusion

The optimal block size in open-pit mining, as of March 9, 2025, is mine-specific, typically ranging from 10–20 meters in height and 20–50 meters in width and length, influenced by bench height, equipment capabilities, and operation efficiency. The Baorixile case study exemplifies practical application, with block sizes around 15–26 m in X, 15 m in Z, and variable Y, aligning with the broader range. This variability underscores the need for tailored approaches, with ongoing research continuing to refine methods for optimization.

Key Citations

- Research on the method of determining the block size for an open-pit mine integrating mining parameters and shovel-truck’s operation efficiency

- Open-pit mining detailed description and insights

- Block size selection and its impact on open-pit design and mine planning detailed analysis

- Open-Pit Mining Definition and operational details

- Method for Optimizing Block Size in Open-Pit Mining Operations research summary

- Open-pit Mining operational challenges and insights in northern regions

- Open Pit Mining comprehensive chapter on methods and parameters

- Mining Strip Open-Pit Quarrying global practices and techniques

- Open Pit Mining overview and engineering applications

Leave a comment