Table of content

Iron and Steel Support in Underground Mining

Iron and steel are extensively used in underground mining for structural support. These materials are employed in the form of rigid and yielding props, beams, girders, reinforcement in concrete, corrugated sheets, and roof/floor bolts.

Steel Props Used in Mining

Steel props are categorized into two main types:

- Rigid Props

- Yielding Props

1. Rigid Props

A common type of rigid prop is a horizontal steel girder with the web cutaway and flanges turned over at one or both ends. If a rigid prop buckles under load, it can be straightened using hydraulic pressure at the pit bottom. In some cases, a timber core extends 25 to 40 mm beyond the steel pipe at both ends, allowing it to yield slightly under roof weight.

2. Yielding Props

Yielding props are designed to absorb roof pressure while maintaining support. These include:

a) Friction Props

MAMC Friction Props (Type FP3) consist of two seamless steel tubes. The inner tube is secured to the outer tube with a spring locking pin, preventing full extension beyond the designed length.

- A clamp unit at the top of the outer member provides friction grip by hammering locking wedges alternately.

- Special coatings protect against corrosion and enhance frictional characteristics.

- The design ensures quick load acceptance and reduced weight relative to load capacity.

b) Hydraulic Props

Hydraulic props function as hydraulic jacks and are widely used in mechanized longwall mining.

- They consist of two oil-filled cylinders, with the upper one telescoping into the lower one.

- A piston head seals the inner and outer cylinders, ensuring controlled downward movement only when loads exceed designed limits.

- Hydraulic props can immediately take three-quarters of the maximum load (yield load) and yield at the designed load level.

Two systems are used for oil pressure buildup:

- Closed Circuit System – Features a built-in pump operated by an external handle.

- Open Circuit System – Uses an external pump connected via high-pressure hoses, serving multiple props simultaneously.

MAMC Hydraulic Props: These include components such as an inner tube, pressure cylinder, pump cylinder, guard tube, non-return valve, main piston, and release valve. The props operate with hydraulic fluid, typically a mixture of water and 10% suitable oil.

- The initial bearing pressure is between 5-8 tonnes.

- Yielding pressure is set between 200-500 kgf/cm².

- Hydraulic props should be handled carefully to prevent oil-sealing capacity loss due to scratches or debris.

Self-Advancing or Walking Supports

These supports are open circuit-type hydraulic chocks, capable of retracting, shifting, and re-erecting using hydraulic pressure.

- A worker only needs to guide the roof bars, while hydraulic cylinders perform the movements.

- Used in longwall mining, first introduced in India at Monidih Colliery.

4-Leg and 6-Leg Canopy Supports

- Powered roof supports walk by alternating between two sets of hydraulic props.

- Movement distance per shift is approximately 0.6 meters.

- 6-leg supports are suited for coal seams between 1450 mm and 2360 mm thick.

Shield Supports

- Provide continuous canopy coverage along the coal face.

- Protect against falling debris with a Venetian-blind-type flushing shield or a sloping rigid shield.

- Equipped with hydraulic agitators and loading doors for efficient coal handling.

- More expensive than chock supports but offer enhanced stability.

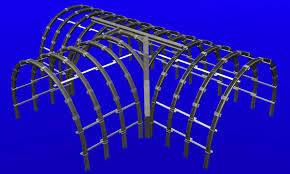

Steel Arches

Steel arches are used for permanent and semi-permanent roadway support.

- Constructed from heavy-section rails, shaped into an inverted U.

- Assembled underground using fishplates, bolts, and nuts.

- Commonly installed without sole plates or lids.

- Wooden laggings are added for stability.

- Not recommended in Indian mines where the strata may descend.

Corrugated Galvanized Iron (CGI) Sheets

- Used in mines to cover girders or support high roofs.

- Often used to pack roof cavities with sand or boiler ash.

Leave a comment