1. Timber Props

Timber props are vertical wooden supports placed between the roof and floor of roadways, mainly in coal mines. In metal mines, they are sometimes called stulls. The primary function of a timber prop is to support the roof while allowing slight yielding under the roof weight to absorb stress effectively.

Strength and Yielding Mechanism

A timber prop is strongest when the load acts parallel to its length. However, a controlled yield is essential for effective support. This is achieved through:

- Tapering at the foot or top – This allows the prop to compress slightly under load.

- Providing a lid at the top – A lid acts as a cushion between the roof and the prop, distributing pressure more evenly.

Proper Erection of Timber Props

- Flat seams: Props are erected vertically.

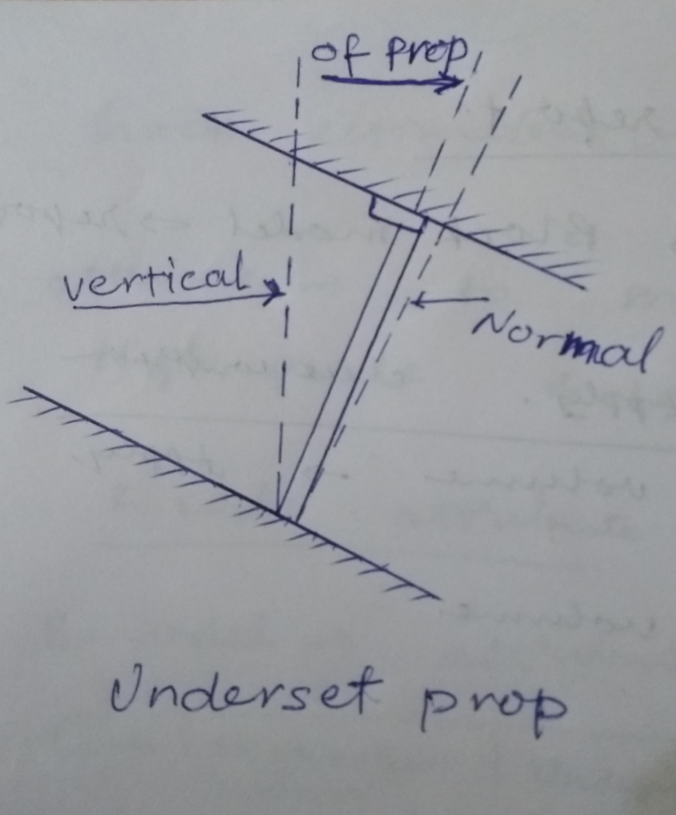

- Inclined seams: The axis of the prop should be normal to the dip of the seam for maximum resistance.

- Underset props: These are props placed at an angle between vertical and normal to the seam. Their use is rare as it is difficult to judge whether they are set correctly.

Base Requirements for Props

Props must be placed on a solid floor and not on loose debris or packing, except in emergencies. If a prop must be set on loose material, it should rest on a flat base piece at least:

- 5 cm thick

- 25 cm wide

- 0.9 m long

If the floor is soft, a base piece prevents the prop from penetrating into the ground.

2. Setting Up Timber Props

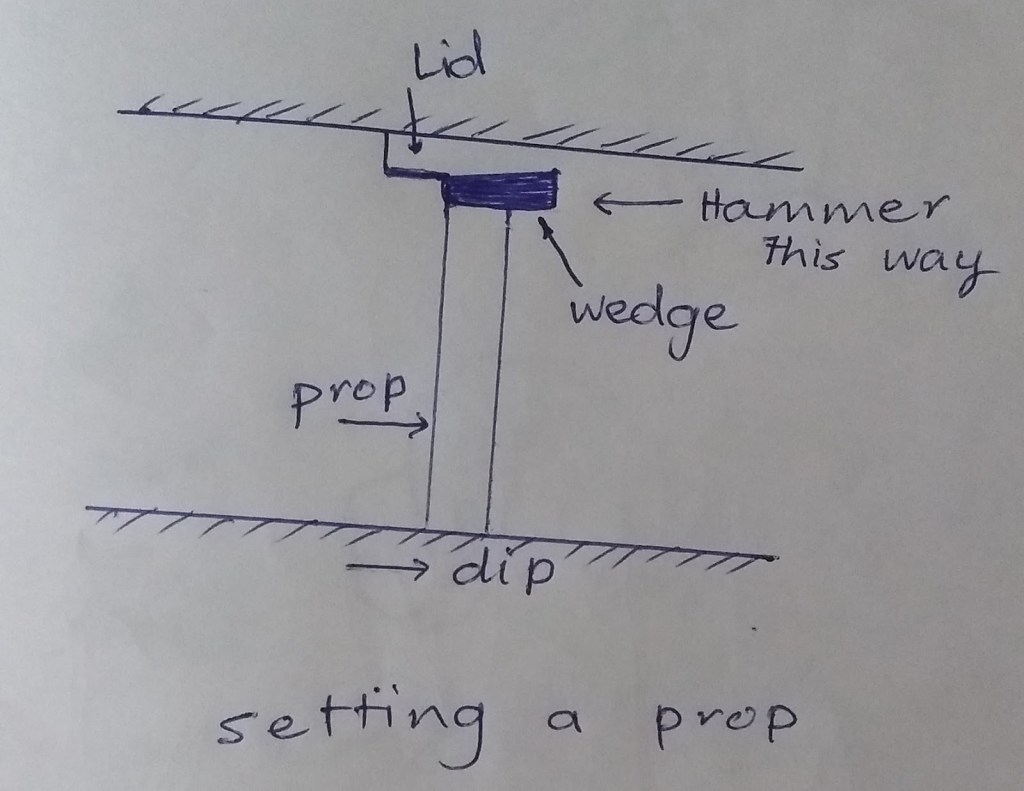

- Positioning: The prop is held upright at the designated spot.

- Lid Placement: A lid (not nailed) is placed on top.

- Wedge Adjustment: A wedge is hammered between the lid and the prop to tighten the assembly.

- Crack Support: If cracks or slips are present, the lid should be placed across them for better support.

Special Considerations

- For roofs below 2.5m: A single wedge-lid combination is often used instead of separate pieces.

- For higher roofs (above 2.5m): Two methods are used:

- Plumb Bob Method: A plumb bob is used to align the prop with the roof. Timber helpers hold the prop while a worker places the lid and wedges.

- Hole in the Floor Method: A shallow hole (25mm deep) is made in the floor to secure the prop’s bottom. The prop is laid on the ground, lifted upright, and wedged into place.

- Inclined Seams: For steep inclines (greater than 1:5), the foot of the prop is secured in a stamp hole to prevent movement.

3. Tapered Props

Tapered props have one end tapered (200-500mm) while the other end has a lid. These are used in areas where:

- The floor is hard

- The roof is soft

Under increasing pressure, the tapered end crushes slightly, allowing controlled yielding to prevent sudden roof collapse.

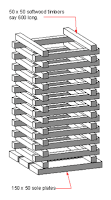

4. Timber Bars

Timber bars act as horizontal beams supporting the roof. Their placement depends on pillar strength:

- Strong coal pillars: Bars are placed in holes drilled into the pillar (minimum depth: 500mm).

- Weak coal pillars: Bars are placed on vertical props for additional support.

For circular bars, the top of the prop is hollowed to match the bar’s shape. Alternatively, the bar can be flattened at each end for better stability.

Additional Support: Wooden Laggings

If the roof is uneven, wooden laggings (flat pieces of wood) are used to improve surface contact and load distribution.

5. Safari Supports

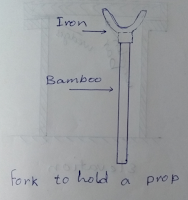

Safari supports provide a faster alternative to traditional timber bars. Normally, crossbars require holes to be manually cut into coal pillars, which is time-consuming. Safari supports replace manual cutting with:

- Drilling holes using coal drills

- Using mild steel clamps to hold crossbars

Advantages

- Faster installation: A crossbar can be installed in 15-20 minutes, compared to 2-2.5 hours for traditional methods.

- Reusable clamps: The clamps can be recovered and reused multiple times.

- Withstands blasting effects: They provide immediate roof support after coal extraction.

- Application in depillaring areas: Used for extracting floor coal and increasing gallery height up to 5m.

Disadvantages

- Requires strong coal pillars

- Reduces gallery height in thin seams

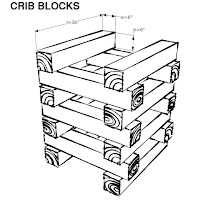

6. Wooden Cog, Chock, or Crib

A chock (cog or crib) is a stacked wooden support made of sleepers arranged in a crisscross pattern. It covers a larger area than props and is used where:

- The roof is unstable over a wide area

- Main roadways pass through weak coal pillar zones

Regulation Requirements

Cogs are mandatory in:

- Goaf edges

- Junctions of splits and galleries

- Depillaring areas in bord-and-pillar workings

- Break-off lines at longwall faces

Construction Guidelines

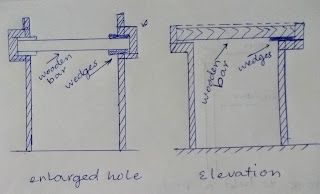

- Only rectangular sleepers or sleepers with two opposite sides flattened should be used.

- Minimum dimensions:

- Sleepers: 1.2m (for roof height up to 3m), 1.5m (for higher roofs)

- Cross-section: At least 100mm × 100mm

- Cogs must be placed on a firm foundation, not loose debris.

- A flat excavation (25-50mm deep) is recommended to ensure stability.

- Wedges are hammered in to tighten the chock against the roof.

Special Cases

Corner props are sometimes added for extra stability:

- In extremely weak roofs

- At goaf edges

- At gallery junctions

- On steep floors (>1:5 gradient)

To dismantle a chock, removing the wedge loosens the structure, making it easy to withdraw the sleepers.

Leave a comment