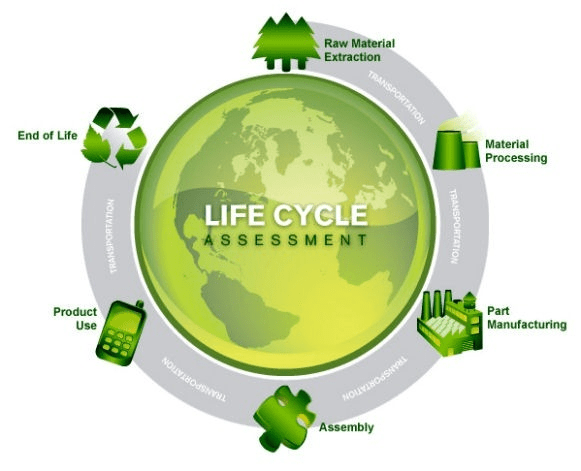

Life-Cycle Assessment (LCA)

A life-cycle assessment (LCA), also known as life-cycle analysis, ecobalance, and cradle-to-grave analysis, is a technique used to evaluate the environmental impacts associated with all stages of a product’s life cycle. This assessment covers the entire process from cradle-to-grave—including raw material extraction, materials processing, manufacturing, distribution, use, repair and maintenance, and disposal or recycling.

Objectives of LCA

Life-cycle assessments aim to provide a comprehensive perspective on environmental impacts by:

- Compiling an inventory of relevant energy and material inputs and environmental releases.

- Evaluating potential impacts associated with identified inputs and releases.

- Interpreting the results to support informed decision-making and environmental improvement strategies.

Life-Cycle Assessment of Platinum Group Metals (PGM LCA)

Based on the International Platinum Group Metal Association (IPA) LCA study, the following environmental impacts and benefits of PGM production were identified:

I. Environmental Impacts

a. Electricity Demand

Power consumption during mining and ore beneficiation is the most significant environmental impact of PGM production. This is largely due to the:

- Low-grade ore and challenging mining conditions.

- South African power grid’s composition, where over 90% of electricity is generated from burning hard coal.

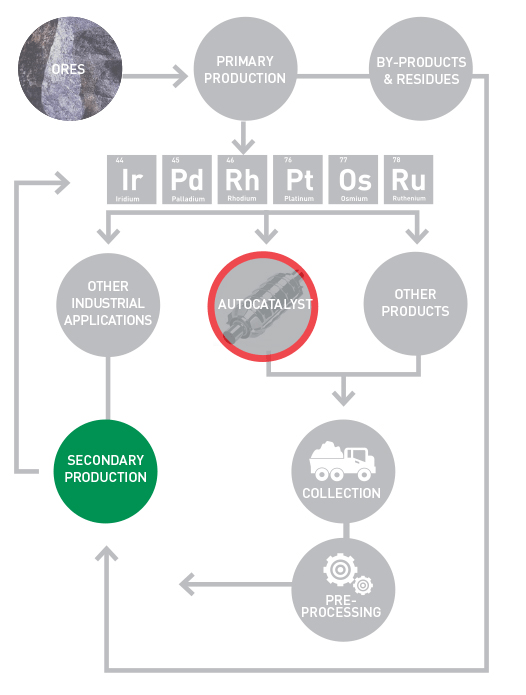

b. Recycling Reduces Impact

Secondary production (recycling) has a significantly lower environmental impact than primary production. This is primarily due to the higher concentration of PGMs in recycled materials compared to mined ores.

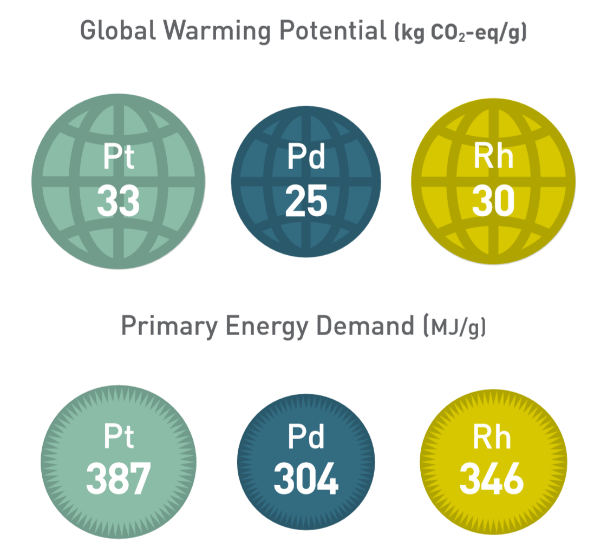

c. Global Warming Potential (GWP) and Primary Energy Demand (PED)

- GWP measures the greenhouse gas emissions of PGM production and is expressed in kg CO2-equivalent per gram (kg CO2-eq/g). It represents the amount of global warming caused by various gases relative to carbon dioxide.

- PED quantifies the energy required to produce PGMs, calculated in megajoules per gram (MJ/g) of PGM produced.

II. Environmental and Societal Benefits

a. Autocatalysts

The environmental benefits of using catalytic converters far outweigh the emissions produced during their manufacturing. These converters, which rely on PGMs, play a critical role in reducing vehicle emissions.

b. Reduction of Harmful Emissions

Catalytic converter systems in modern vehicles (e.g., EURO 5 gasoline and diesel vehicles) reduce the release of harmful pollutants such as:

- Carbon monoxide (CO): Reduced by 63% (petrol) and 82% (diesel) since 1993.

- Hydrocarbons (HC): Reduced by 50% (petrol) since 2001.

- Nitrogen oxides (NOx): Reduced by 84% since 2001.

- Particulate matter (PM): Reduced by 96% (diesel) since 1993.

Over 1.3 tonnes of these pollutants are prevented by catalytic converters in a single vehicle during 160,000 km of use.

c. Improved Public Health

Emission reductions positively impact human health, as quantified by the Disability-Adjusted Life Year (DALY) metric developed by the World Health Organization (WHO). Reduced exposure to toxic pollutants improves air quality and decreases disease burdens.

Keywords

life-cycle assessment (LCA), life-cycle analysis, cradle-to-grave analysis, environmental impacts, platinum group metals (PGM), recycling benefits, global warming potential (GWP), primary energy demand (PED), autocatalysts, pollution reduction, health impacts, DALY, IPA study

Leave a comment